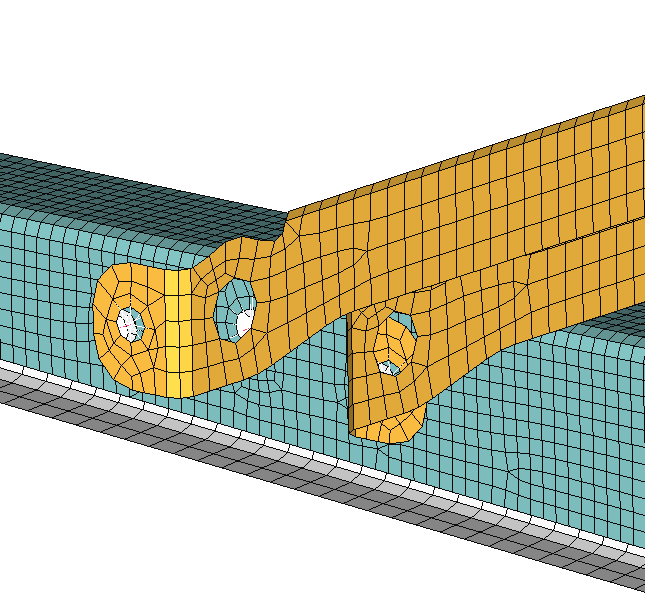

FEA meshing

FEA pre-processing is the most time consuming process

It could take days of effort especially if the part is complex and accuracy level has to be high.

Poor quality mesh misleads FEA results which negatively impacts project success – we recommend to outsource pre-processing if you having a tight time schedule and limited sources.

Ready to use solutions

– FEA pre-processing and Model building

– FEA meshing – mapped meshes for simple and complicated geometries

– Boundary conditions – constraints, external forces, loads, pressures

Common cell shapes

1D

– Two noded beams

– N – noded beams

2D

-Triangle

-Quadrilaterial

3D

– Tetrahedron

– Pyramid

– Triangular prism

– Hexahedron

Benefits

Reduction of development time

Reduction of project costs

High quality mesh – accurate results in FEA